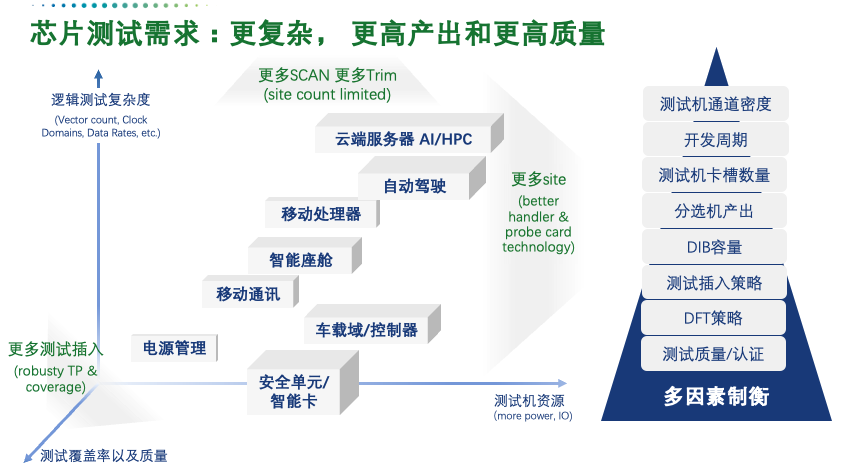

Chip testing is a complex process, and the testing requirements for all chips are diverse. From the perspective of testing machine development, there are many balancing factors, including whether the testing machine has so many channels, whether it has such a high density, whether product development can be fast, and whether the number of card slots in the testing machine can be relatively large to meet these requirements? Is there such a large output of automated equipment, including sorting machines and probe stations? And some safety function certifications, such as on-board certification ACQ100, ISO26262, and so on. These are some checks and balances that need to be considered as test machine suppliers and test machine partners, and it is difficult to find a balance between the two. So testing machines need to do more test inserts, more SCANs, more trims, and more test units, which is a challenge it poses.

Whether it's for automotive chips or other types of chips, an irreversible trend in the semiconductor industry is the continued increase in chip complexity, placing higher requirements on chip testing.

First, the cost of testing will become higher and higher, and the proportion will become higher and higher, going up from about less than 10%. Using higher concurrent testing numbers and more test resource testing machines can further reduce the overall cost. Secondly, there is an increasing demand for testing machines, as there are increasing requirements for chip test vectors and testing resources, which may also require various test equipment to possess such capabilities. The last point is the self-development of the testing industry. Currently, more and more new testing methods are being applied to new chips, and these new testing methodologies will continue to be added to the testing industry as new testing standards.

ThermoTST heat flow hood can be compatible with various brands of ATE devices, and is easy to operate. It can accurately control hot and cold air. It is suitable for various semiconductor chips, microelectronic devices, integrated circuits (SOC, FPGA, PLD, MCU, ADC/DAC, DSP, etc.), flash memory Flash, UFS, eMMC, PCBs, MCMs, MEMS, IGBT, sensors, small module components Optical communication (such as transceiver high and low temperature testing, SFP optical module high and low temperature testing, etc.), the electronic industry, and other reliability tests such as characteristic analysis, high and low temperature temperature temperature variation testing, temperature impact testing, failure analysis, etc. The unique single compressor technology is a system that can release - 80 ° C temperature at a flow rate of 18 SCFM (8.5 l/s), greatly improving the speed and accuracy of ATE testing, making it an indispensable partner for ATE testing machines.

Part of the content of this article is reproduced from TERADYNE. If there is any infringement, please contact to delete it. Thank you!