Significance of reliability assessment analysis:

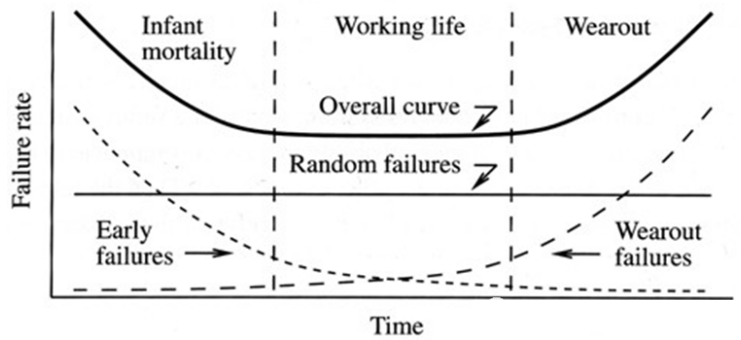

Reliability is a measure of product durability. The life cycle of our main typical IC products can be expressed by a Bathtub Curve.

As shown in the figure above, the failure causes of integrated circuits can be roughly divided into three stages:

Region (I) is known as the premature period. At this stage, the failure rate of products rapidly decreases. The reason for the failure is the defects in the IC design and production process;

Region (II) is called the Useful life period. At this stage, the failure rate of products remains stable, and the reasons for failure are often random, such as temperature change, etc;

Region (III) is called the Wear-Out period. At this stage, the failure rate of products will rise rapidly. The reason for failure is the aging caused by long-term use of products.

The Thermal Control System TS-780 developed by Cryogenic Technology is applied to the failure analysis and characteristic analysis of chips, providing a broader temperature range of - 80 ℃ to+225 ℃ for chip testing, and providing a very advanced temperature conversion test capability. Temperature conversion from - 55 ℃ to+125 ℃ for about 10 seconds; It accelerates the testing speed of DTF in ATE, and can be applied to high and low temperature temperature change test, temperature impact test and other reliability tests. After long-term multi-condition verification, it meets the requirements of various production and engineering environments. TS-780 is pure mechanical refrigeration, without liquid nitrogen or any other consumable refrigerant.