After the chip is packaged, there may be potential defects, which may lead to unstable chip performance or potential defects in function. If these chips with potential defects are used on key equipment, they may fail, causing property loss or life danger to users. The purpose of aging test is to put the chip at a certain temperature and then apply a specific voltage to accelerate the chip aging, so that the chip reliability can pass the early failure period in advance and directly reach the accidental failure period (accidental failure period), ensuring the stability and reliability of the chip working performance delivered to customers.

Common aging standards:

① The IC aged for 1000 hours at 125 ℃ can be guaranteed to last for 4 years;

② The IC aged for 2000 hours at 125 ℃ can be used for 8 years;

③ The IC aged for 1000 hours at 150 ℃ can be used for 8 years;

④ The IC aged for 2000 hours at 150 ℃ can be used for 28 years;

Specific test conditions and estimation results can refer to specific standards.

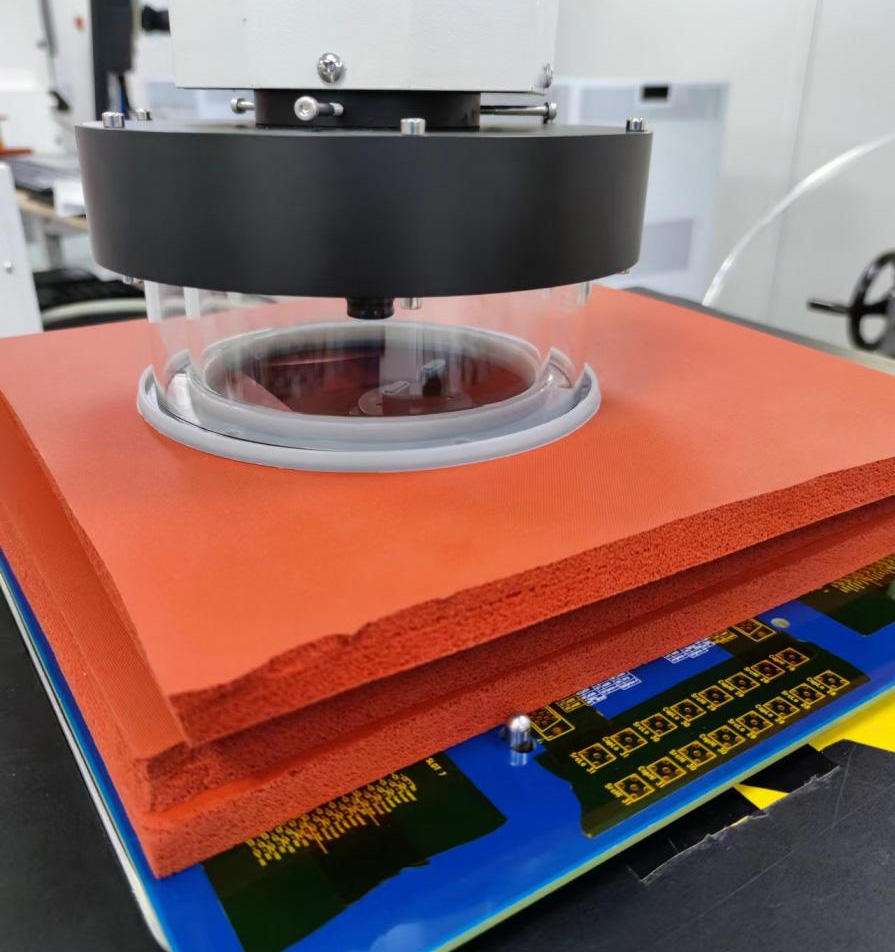

Targeted aging fixture features for BGA packaging:

① The use of imported three-temperature double-head probe makes the data transmission distance between IC and PCB shorter, thus making the test more stable and more frequent.

② The PCB and socket are positioned and locked with locating pins, connected and fixed with screws, and easy to disassemble and maintain.

③ The shell is made of PEEK engineering plastic material, which can age continuously for more than 3000 hours under 155 ℃;

④ The upper cover adopts an integrated aluminum radiator, which can meet the high power dissipation of the chip;

⑤ It adopts a clamp-on structure, which is convenient to close and open, and the pressure on the gland is balanced and stable;

Chip testing is not only "critical" and "harsh", but also requires the control and participation of the whole process. From chip design, chip startup verification, chip streaming to mass production stage testing, each stage needs to solve the corresponding demands, and how to continuously optimize the process, improve program efficiency, reduce time, and reduce costs. Testing in the mass production stage is particularly important, so chip testing is not only a matter of cost, but also the key to balance quality, efficiency and cost. Of course, in addition to chip aging test, other reliability tests are also very important.

The Thermal Control System TS-560 developed by Cryogenic Technology is applied to the failure analysis and characteristic analysis of chips. It can carry out the test with clamps, providing a broader temperature range of - 70 ℃ to+225 ℃ for chip testing, providing a very advanced temperature conversion test capability. Temperature conversion from - 55 ℃ to+125 ℃ for about 10 seconds; It accelerates the testing speed of DTF in ATE, and can be applied to high and low temperature temperature change test, temperature impact test and other reliability tests. After long-term multi-condition verification, it meets the requirements of various production and engineering environments.