The main purpose of IC testing is to distinguish qualified chips from unqualified chips, ensuring the quality and reliability of the product. With the rapid development of integrated circuits, their scale is increasing, and the requirements for circuit quality and reliability are further raised. The testing methods for integrated circuits are also becoming increasingly difficult. Therefore, researching and developing IC testing is of great significance. As an important part of IC testing, it is increasingly important to study the generation methods of test vectors.

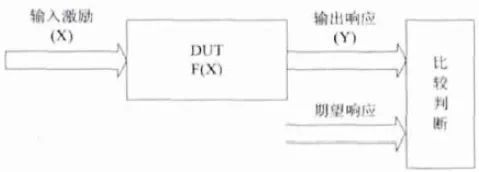

IC testing refers to providing test excitation (X) to the device under test (DUT) based on its characteristics and functions, and comparing the DUT output response (Y) with the expected output to determine whether the DUT meets the requirements.

According to device types, IC testing can be divided into digital circuit testing, analog circuit testing, and mixed signal circuit testing.

Digital circuit testing is the foundation of IC testing. Except for a few pure analog ICs such as operational amplifiers, voltage comparators, analog switches, etc., most ICs used in modern electronic systems contain digital signals. Digital IC testing generally includes direct current testing (DC), alternating current testing (AC), and functional testing.

DC testing is a steady-state testing method based on Ohm's law used to determine device parameters. It verifies electrical parameters in the form of voltage or current. DC parameter testing includes contact testing, leakage current testing, conversion level testing, output level testing, power consumption testing, etc. The commonly used testing methods for DC testing include pressurized current measurement (FVMI) and pressurized pressure measurement (FIMV), with the main considerations being testing accuracy and efficiency. The quality of the circuit can be determined through DC testing. By conducting contact testing to determine the open/short circuit status of IC pins, leakage testing can reflect the process quality of the circuit from a certain perspective, and conversion level testing can verify the driving and noise resistance of the circuit. DC testing is the foundation of IC testing and a fundamental means of assessing circuit performance and reliability.

Communication (AC) parameter testing is the process of verifying time related parameters over time. In fact, it measures the time relationship of a circuit during operation, such as the operating frequency, the relationship between input and output signals over time, and so on. Common measurement parameters include rise and fall time, transmission delay, establishment and retention time, and storage time. The communication parameters are most concerned with maximum testing rate and repeatability, followed by accuracy.

Functional testing is used to verify whether an IC can perform the expected work or function as designed. Functional testing is the foundation of digital circuit testing. It simulates the actual working state of an IC, inputs a series of ordered or randomly combined test patterns, applies them to the tested device at the specified rate of the circuit, and then detects whether the output signal matches the expected graphic data at the circuit output terminal to determine whether the circuit function is normal. Its focus is on the speed of graphic generation, edge timing control, input/output control, and masking selection.

Functional testing is divided into static functional testing and dynamic functional testing. Static functional testing is generally conducted using a truth table method to identify fixed type (Stuckat) faults. Dynamic functional testing is conducted at a speed close to the operating frequency of the circuit, with the aim of verifying the functionality and performance of the device at or above its actual operating frequency.

Functional testing is generally conducted on ATE (Automatic Test Equipment), which can provide complex timing test stimuli based on the simulated waveforms of the device during the design phase, and perform real-time sampling, comparison, and judgment of the device's output.

This article is reprinted from the internet. If there is any infringement, please contact us to delete it. Thank you!