Hidden Killer of Sealed Components

There is a risk that sealed components may be overlooked by the manufacturer during the production process and lead to component failure during subsequent use, which is the excess small loose particles that appear inside the sealed components.

In the process of producing sealed components with cavities, it is possible to encapsulate some excess small particles such as solder slag, rosin, metal shavings, sealant, dust, etc. in the sealed cavity. Under strong external vibration or impact environments, the excess small particles in these cavities will be activated by external force excitation, and will randomly collide with the cavity wall and other structures inside the cavity, which may lead to failure of components such as short circuits, inactivity, and misoperation, resulting in quality accidents.

This excess small loose particles in sealed components have become a hidden killer of sealed components due to their inability to be directly observed. Particle Impact Noise Detection (PIND) tests can effectively detect excess small loose particles in sealed components with inner cavities, avoiding quality accidents.

PIND Test Principle

PIND test is a non-destructive test, which aims to detect free particle in the packaging cavity of components. PIND uses vibration devices, driving devices, impact devices or tools, threshold detectors, adhesives, sensors, and other equipment to add a sinusoidal vibration and pulse impact environment that approximates the actual application conditions to the components. When the particle mass is large enough, it is detected by a series of vibration and impact cycles, which excite the sensor when the particle collides with the device packaging shell.

PIND trial case sharing

Device sample information

Device Name: Integrated Circuit

PIND test items and conditions

|

Test sequence |

Test conditions |

|

Impact before testing |

1000g,3times |

|

vibrate |

20g,1times,60HZ,3s |

|

Simultaneously impact with the previous vibration |

1000g,3times |

|

vibrate |

20g,1times,60HZ,3s |

|

Simultaneously impact with the previous vibration |

1000g,3times |

|

vibrate |

20g,1times,60HZ,3s |

|

Simultaneously impact with the previous vibration |

1000g,3times |

|

vibrate |

20g |

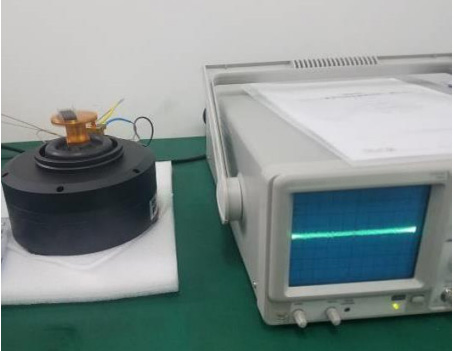

PIND test images

PIND Test Service Capability

Equipped with a particle collision noise detector, it can perform particle collision noise detection (PIND) tests on various types of cavity components such as relays, power modules, crystal oscillators, semiconductor discrete devices, integrated circuits, etc., effectively improving the reliability of electronic components.

This article is reproduced from product testing. If there is any infringement, please contact to delete it. Thank you!