In the vacuum chamber, water vapor molecules are the most typical environmental pollution gases, accounting for 65% to 95% of the residual gases in the chamber. When the vacuum degree reaches 10E-2Pa, water vapor molecules are difficult to discharge from the chamber with ordinary vacuum pumps, which is the typical most side-effect pollution gas and the pollution source of the workpiece, thus affecting the output and quality of the product. In order to quickly reach a higher vacuum, the COOL series water vapor cryogenic pump quickly captures and absorbs the water vapor in the vacuum chamber, assists in vacuumizing, and achieves the required vacuum in a very short time.

The working principle of the COOL series water vapor cryogenic trapping pump is to place a cold trap coil or baffle on the cavity wall of the vacuum chamber or the pump port of the oil diffusion pump. Through the surface of the cooling coil, the low temperature condensation effect can be achieved, and the water vapor molecules or other residual gas molecules of the vacuum pump system can be quickly captured, so as to obtain a clean vacuum environment, improve the output and quality of the product, and improve the quality of the coating, Improve the adhesion and multilayer coating ability of the film.

The COOL series water-vapor cryogenic trap pump has single-stage and double-stage configurations. The two-stage refrigeration can control the refrigeration of each channel separately. The coil or baffle of the two channels of cold trap can be defrosted quickly.

Features

Maximum steam extraction speed 366000L/s

Quickly capture water vapor and oil vapor; Vacuum pumping time can be reduced by up to 75%

The temperature can reach - 120 ℃ to - 150 ℃

20% to 100% of product throughput

Better than liquid nitrogen refrigeration in cost/performance

Cooling capacity up to 4000W

The environment-friendly mixed refrigerant meets the environmental requirements of all applicable regions (Kyoto International Agreement).

Automatic control, supporting remote communication

HD touch screen, convenient panel control

Two-stage refrigeration circuit configuration

Application

Economic choice of replacing liquid nitrogen

In optical coating, winding coating and other functional coating or decorative coating systems, it can be used to suck water vapor in the vacuum chamber to obtain better film quality

Used for cooling devices such as cold traps to prevent diffusion pump from returning

Chemical engineering, liquefied process gas

System

In addition to the COOL equipment unit, the following key components are also provided. If necessary, they can be manufactured according to your specifications:

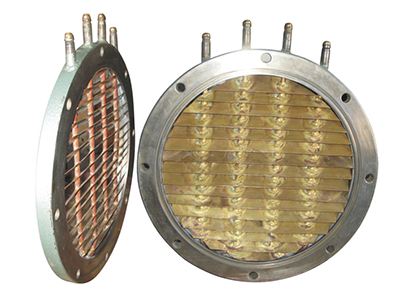

Cold trap coil and baffle

The cold well coil is generally installed in the vacuum chamber, or between the high valve and the vacuum chamber, and is suitable for the occasions where the amount of gas released by the coating material is large. The cold well coil also has the defrosting function, so that the cold well coil can recover to the normal temperature before each door opening, which is conducive to the next vacuum pumping.

The cold trap baffle is generally installed above the diffusion pump, and its main function is to prevent the oil and gas backflow of the oil diffusion pump, at the same time, it can also extract water vapor and improve the vacuum.

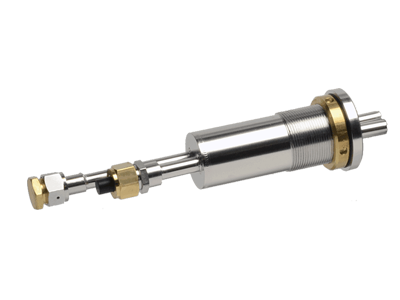

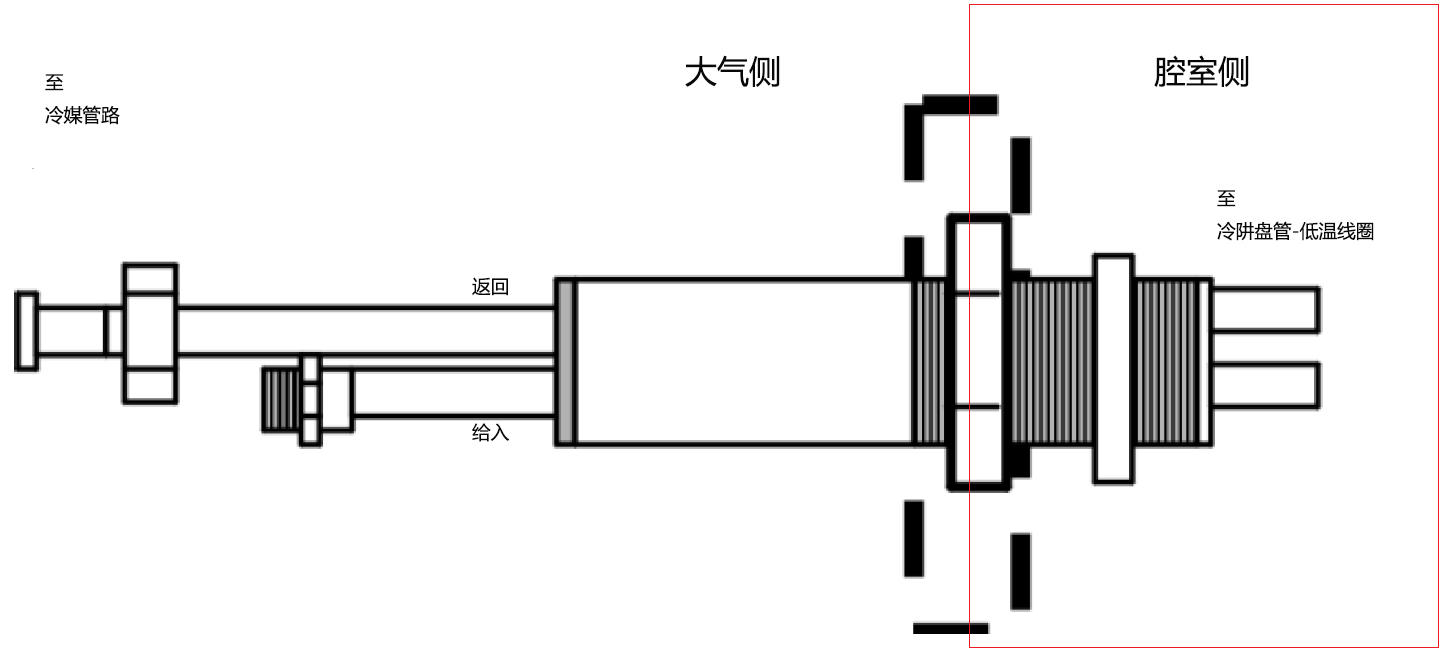

Feeder (can be provided separately or as part of cold trap coil)

The dual-channel provides the flange to enter the true cavity while maintaining the thermal isolation between the inlet pipe and the return pipe. On the outside, the pipe joint can be directly connected with the refrigerant pipeline. On the chamber side, the feed-through and internal cold trap pipes are welded together.

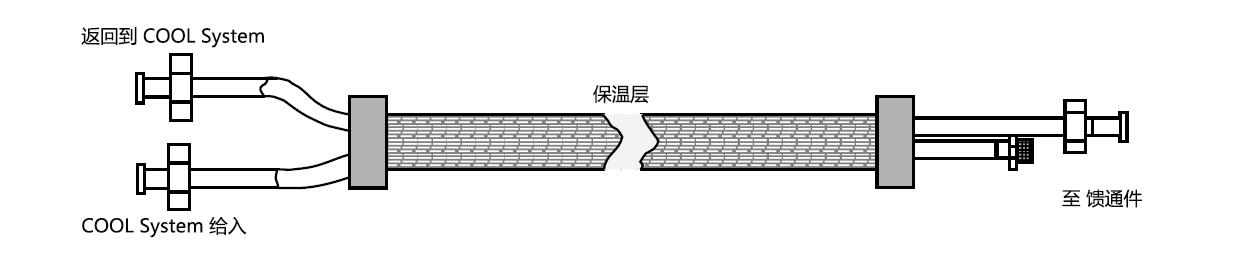

Refrigerator pipeline

Refrigerant pipe "includes a feed pipe and a return pipe with stainless steel pipe connector (Parker or VCR), which can be used together with the COOL system and feed-through parts. Refrigerant pipes are insulated with foam insulation layer to prevent exposure to outdoor air and reduce heat loss.

Water vapor pressure meter

What is the best temperature for effectively capturing water vapor?

To find the best low-temperature surface temperature for your vacuum system, please find the final basic pressure of the system listed below. Then continue to the right column that displays the desired low temperature surface temperature. This temperature represents 90% water vapor capture efficiency.

|

Pressure Torr |

Temperature ℃ |

Pressure Torr |

Temperature ℃ |

|

5×100 |

-25.4 |

5×10-5 |

-104.9 |

|

2×100 |

-34.4 |

2×10-5 |

-109.1 |

|

1×100 |

-40.8 |

1×10-5 |

-112.2 |

|

5×10-1 |

-46.8 |

5×10-6 |

-115.1 |

|

2×10-1 |

-54.3 |

2×10-6 |

-118.1 |

|

1×10-1 |

-59.7 |

1×10-6 |

-121.5 |

|

5×10-2 |

-64.8 |

5×10-7 |

-124.1 |

|

2×10-2 |

-71.2 |

2×10-7 |

-127.5 |

|

1×10-2 |

-75.8 |

1×10-7 |

-129.9 |

|

5×10-3 |

-80.1 |

5×10-8 |

-132.2 |

|

2×10-3 |

-85.6 |

2×10-8 |

-135.2 |

|

1×10-3 |

-89.6 |

1×10-8 |

-137.3 |

|

5×10-4 |

-93.4 |

5×10-9 |

-139.5 |

|

2×10-4 |

-98.2 |

2×10-9 |

-142.1 |

|

1×10-4 |

-101.6 |

1×10-9 |

-144.1 |

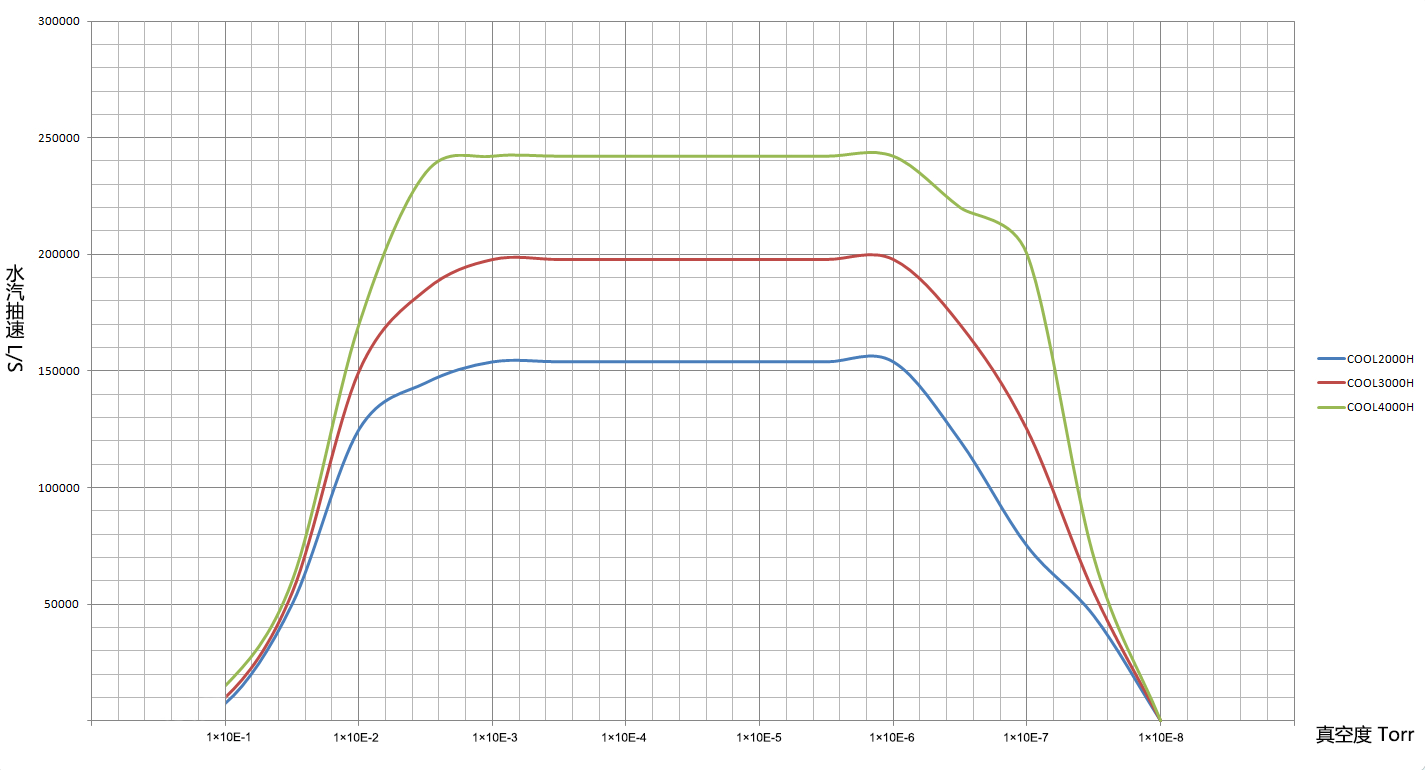

The relationship between the pumping speed and pressure of the Cool System

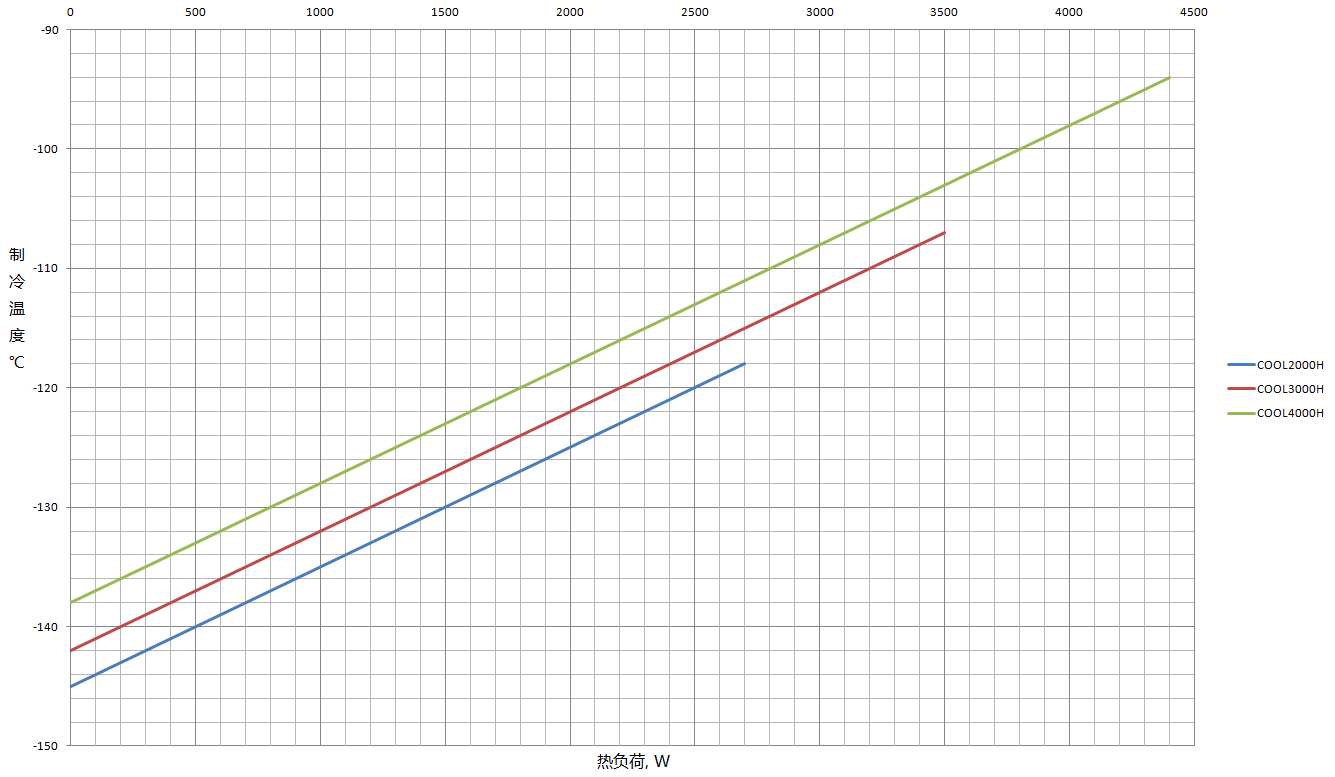

The functional relationship between the average surface temperature of the cold trap and the external heating load

Specifications

|

Type |

COOL2000H |

COOL3000H |

COOL4000H |

|

Maximum cooling capacity(W) |

2700 |

3500 |

4400 |

|

Theoretical maximum pumping speed(L/S) |

228000 |

295000 |

366000 |

|

Theoretical maximum pumping speed in cavityL/S) |

154000 |

198000 |

242000 |

|

Ultimate vacuum(Torr) |

2×10-8 |

2×10-8 |

2×10-8 |

|

Prefabrication cold time |

<30Min |

<30Min |

<30Min |

|

Cooling time |

≤4Min |

≤5Min |

≤6Min |

|

Defrost time |

≤5Min |

≤6Min |

≤7Min |

|

Surface area of cold trap tube ㎡ |

1 |

1.6 |

2.4 |

|

Cooling requirements |

water-cooling,18-32℃,2-4bar |

||

|

Cooling water flow requirements(L/min) |

>20 |

>28 |

>35 |

|

Cooling water interface |

G3/4 |

G3/4 |

G3/4 |

|

Refrigerant |

Environment-friendly mixed refrigerant |

||

|

Control system |

PLC+Touch interface |

||

|

Power |

380-400V, AC , 3PH, 50/60Hz |

||

|

Power |

10Kw |

13Kw |

15Kw |

Optional Accessories

|

Cold trap coil |

Cold trap baffle |

Feedthrough |

Refrigerant pipe |

|

*Different shapes and sizes can be customized |

*Different sizes can be customized |

*Optional Parker and VCR connectors, specification: 1 "or 2" |

*Standard length 2.45m, customizable length |

|

Refrigerant |

cooling-water machine |

||

|

*Compatible with Polycold devices according to device model |

*Compatible with other water cooling equipment according to equipment configuration |

||

Related recommendations