HASS (High Accelerated Stress Screen), also known as High Accelerated Stress Screening Experiment, involves conducting high accelerated stress screening on the production line after obtaining operational or failure limits through HALT testing. Generally, 100% of the products are required to participate in the screening. The purpose is to ensure that the produced products do not have any hidden defects or to find and solve these defects before the products leave the factory. HASS is to find defective products in a short period of time by accelerating stress, shortening the cycle of corrective measures, and finding products with the same problem.

HASS is applied to the production stage of products to ensure that all improvement measures found in HALT have been implemented. HASS can also ensure that new defects are not introduced due to changes in production processes and components. The purpose of High Accelerated Stress Screening (HASS) testing is to detect production quality issues in mass-produced finished products in a very short period of time.

This test consists of three main stages:

● HASS Development (HASS Test Plan Phase)

● Proof of Screen (Plan Verification Phase)

● Production HASS (HASS execution phase)

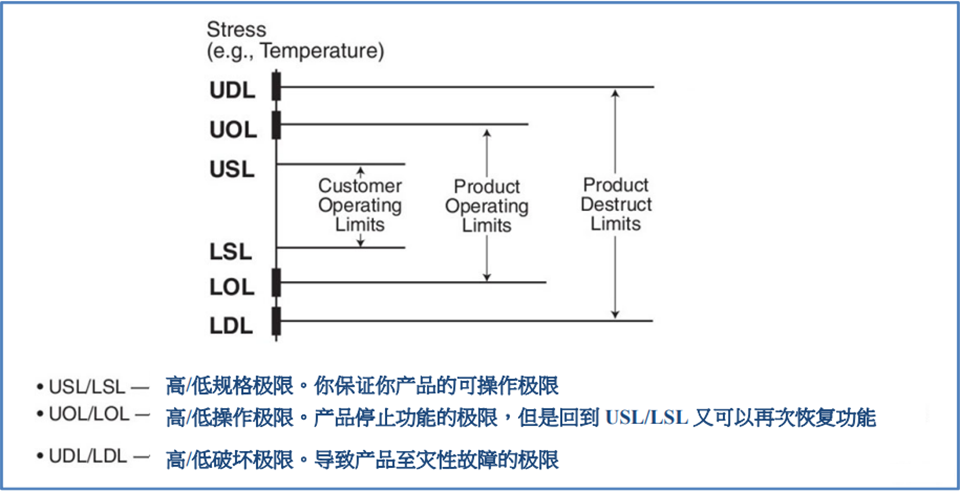

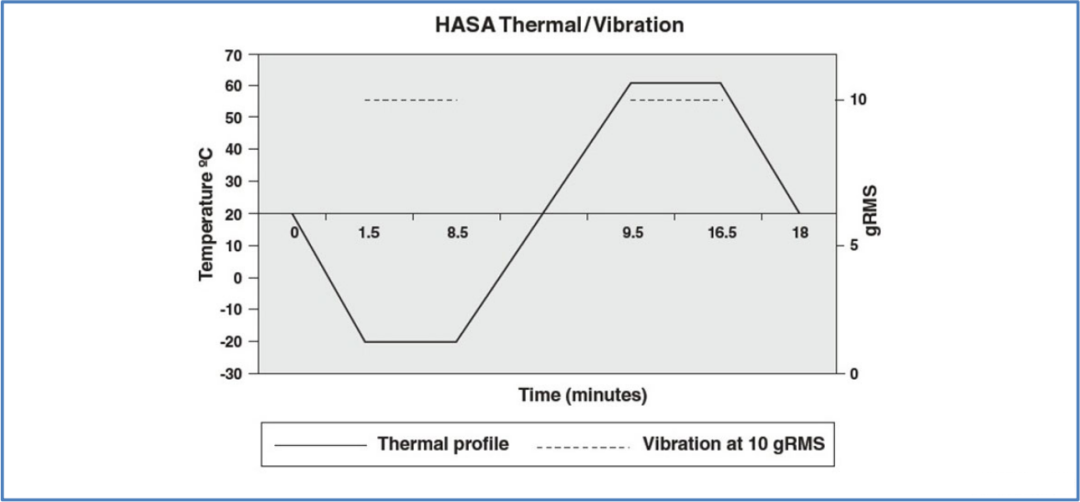

The vibration and temperature limits used in HASS are based on the operational and failure limits found in HALT, and HALT must be performed before HASS to define these limits. The starting point of screening and the validation (POS) process used to demonstrate the safety and effectiveness of screening follow the most commonly recommended methods in the industry narrative of testing procedures. Regarding the typical HASS screening process curve.

The HASS limit is based on the limits discovered by HALT

Typical HASS screening program curve

The HAST developed by Zonglen is a testing equipment used to investigate and analyze when issues related to wear and service life of electronic components and mechanical parts occur. Its purpose is to increase environmental and working stresses, accelerate the testing process, and shorten the lifespan testing time of products or systems. Widely used in IC semiconductors, connectors, circuit boards, magnetic materials, polymer materials, EVA, photovoltaic modules and other related industries.

Characteristics of HAST high-pressure accelerated aging test chamber:

·Standard design is safer: the inner arc design prevents condensation and dripping, in accordance with national safety container specifications

·Multiple protections: multiple human-machine protections for various types of overpressure, overheating, dry burning, leakage, and misoperation

·Higher stability: The control mode is divided into three modes: dry wet bulb, unsaturated, and wet saturated

·Humidity free selection: saturation and unsaturated free setting

·High intelligence: USB data, curve export and save

This article is reprinted from the internet. If there is any infringement, please contact to delete it. Thank you!